Taylor® T-1023

Ampliar foto

Ampliar foto

Taylor® T-1023

Taylor Wheel Loaders are heavy industrial equipment used to move or load materials such as finished lumber, logs & poles (Millyard Applications), wood chips, steel & concrete pipe, demolition debris, raw minerals, recycled material, scrap material, etc. for processing and manufacturing.

Impresión

- Carga de vuelco / recta: 27,679 lbs / 12,555 Kg

- Carga de vuelco / giro completo: 23,416 lbs / 10,621 Kg

- Altura máxima del pasador de bisagra: 155 in. / 3937 mm

- Distancia entre ejes: 120.0 in. / 3048 mm

- Motor: QSB6.7-C175 T4F

- Transmisión: ZF Powershift 4-sp.

- Tipos de archivos adjuntos: Std. horquillas, varias abrazaderas, cubo volcado

- Tipo de freno: Disc mojado

- Voltios: 24

- Neumático: 20.5-R25 L3 x 4

Standard Features: T-1023

- 27,679-lb Straight Tipping Load

- 23,416-lb Full Turn Tipping Load

- 12-ft 11-in Maximum Hinge Pin Height

- Cummins QSB6.7 C-167 HP Tier-4 Final diesel engine

- Automatic Idle System

- Cummins air cleaner w/safety element & restriction indicator

- 4-Speed ZF Powershift Transmission

- Powertrain Protection System for engine and transmission

- LGNA Limited Slip Drive Axles with Wet Disc Brakes

- 20.5 R25 L3 Pneumatic Front Tires

- 20.5 R25 L3 Pneumatic Rear Tires

Chassis

- Heavy Duty Steel Chassis

- Z-Bar Linkage features optimized geometry that positions the load closer to the tires and improves distribution of stress.

- Auxiliary Valve Lines pre-plumbed for accessory functions

- Hinge Pins and Lift Arm Mounting Plates are optimized with special heat treat process to increase strength.

- Manually Actuated Fiberglass Hood ensures easy access to the engine and its easy-to-reach service points.

- Both Rear Full Fenders swing out for easy access to the engine compartment.

- Full rubber floor mat for dampening of vibration and noise.

- The 4-Bar steps are widely spaced to allow debris to fall through.

- Auto-lube system

- Articulation Locking Bar

- Hydraulic Quick Coupler

- Tow Hitch

- Belly Guard

Cab

- Panoramic View Cab with curved front glass (includes dome light, wide angle mirrors, handrails and full rubber black floor mats).

- Certified ROPS/FOPS cab

- Adjustable Grammer Air Suspension Seat provides maximum comfort and reduces operator fatigue

- Adjustable Steering Column

- Single Joystick Control

- Gauge group that includes engine/transmission levels and temperatures, hydraulic temperature, voltage, hour meter, brake oil pressure, Fuel/DEF level and Engine faults.

- Front and Rear Windshield Wiper

- Operator Restraint System (Orange, anti-cinch seat belt)

- Secondary Steering (emergency)

- Heat, Air Condition and Rear Windshield Defrost

- Rear View Camera Display

- Sun Visor

- Fire Extinguisher

- Ride Control

Electrical

- 24-volt electrical system

- Maintenance free Heavy-duty batteries

- Two front halogen lights (with high/low beam)

- Two front LED lights (mounted top of cab)

- Two rear LED lights (mounted top of cab)

- Electric horn

- Amber strobe light

- Reverse actuated warning alarm

Vehicle Information Package

- Operator’s Guide

- Maintenance and Service Documentation

Adjuntos Disponibles

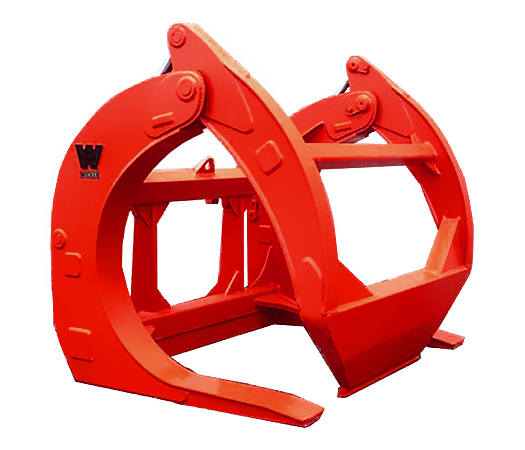

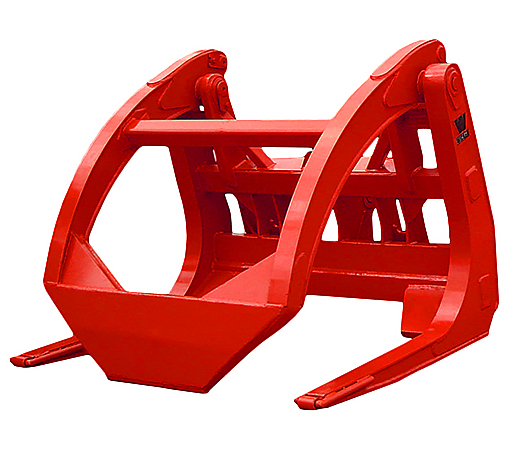

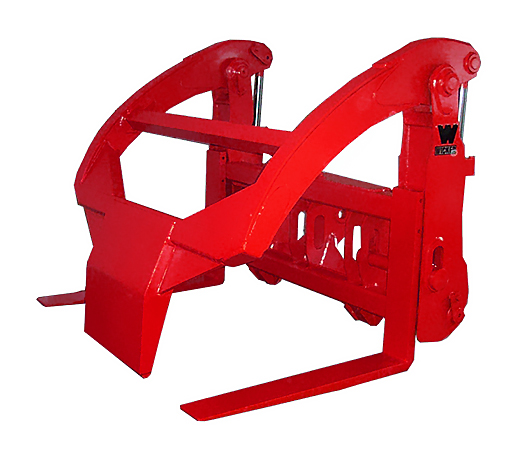

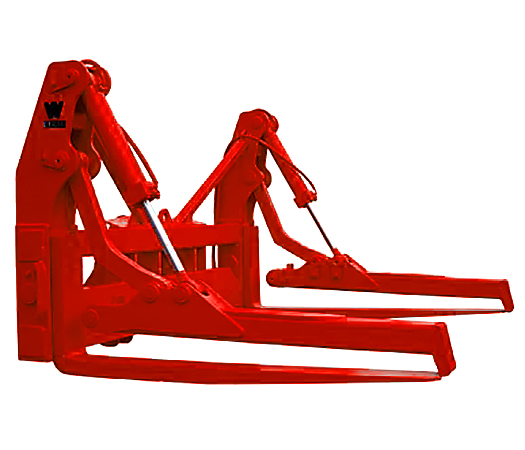

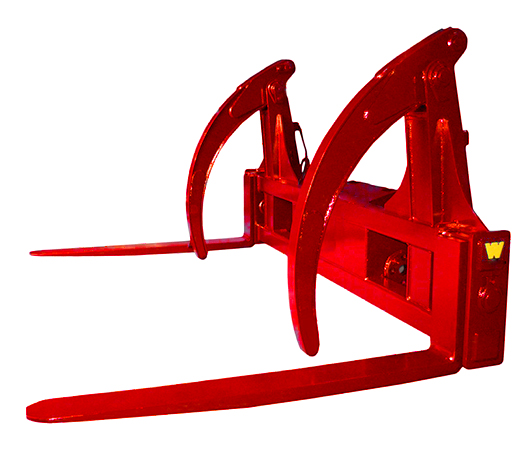

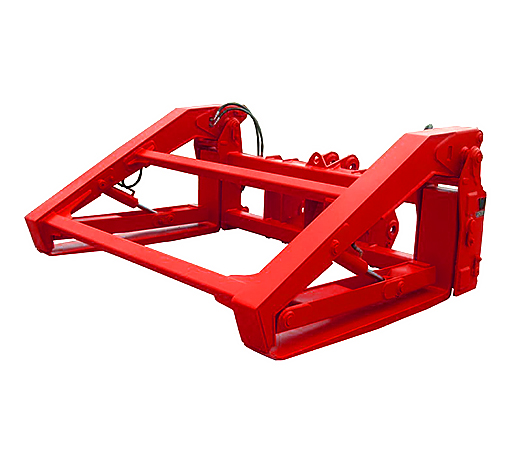

1. Log & Pole Grapple

2. Mill Yard Fork

3. Log & Lumber Fork with Hold-Down

4. Pipe Forks with Individual Top Clamp

5. Pipe Forks with Radius Top Clamp

6. Pipe Forks with Dual Top Clamp

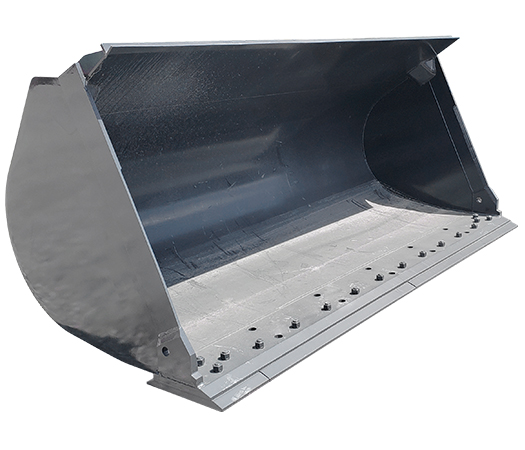

7. General Purpose Bucket

8. Wood Chip Bucket

9. Scrap Grapple

Taylor International® proporciona Cargadores de ruedas ventas, repuestos y servicio para Centro y Sudamérica. Taylor Forklifts y Material Handling Equipment están diseñados, fabricados y fabricados en los Estados Unidos de América. Industrias como el acero, el aluminio, la madera, la madera, el concreto, el prefabricado, el breakbulk, el intermodal, los puertos, los ferrocarriles y los estibadores suelen utilizar productos Taylor®.

Para obtener información sobre cualquiera de los productos que ofrecemos. Por favor contáctenos